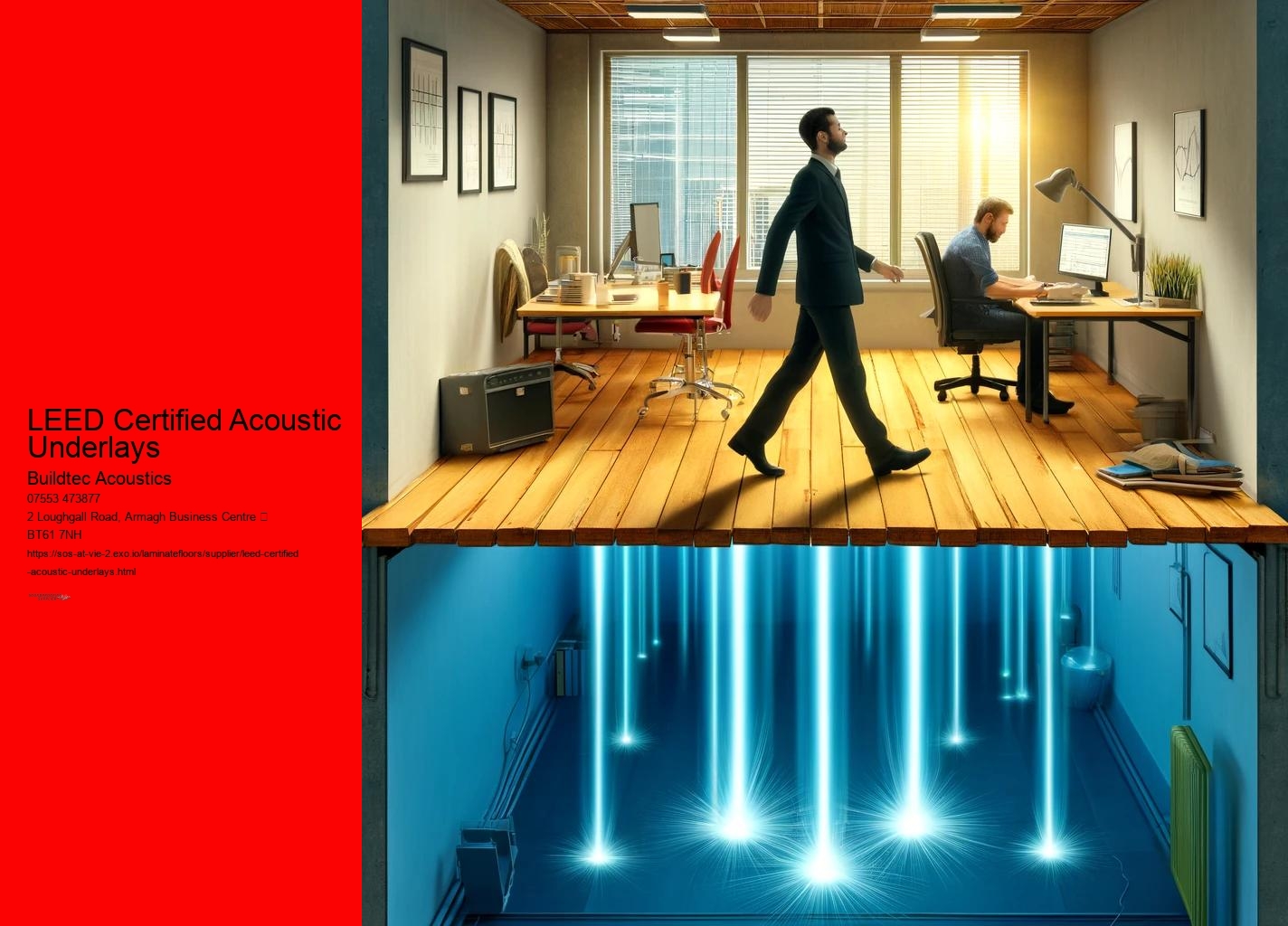

With acoustic underlays, these sounds are absorbed, contributing to improved room acoustics. Acoustic Underlay Maintenance Tips . Soundproofing Material Products from this Soundproofing Supplier are affective acoustic solutions. The use of acoustic underlay under wood flooring or laminate flooring can significantly reduce noise levels in rooms. Additionally, these materials have low volatile organic compound (VOC) emissions, contributing to a healthier indoor environment.

LEED Certified Acoustic Underlays - cement

- heat transfer

- wool

- ceramic

- adhesive

- volatile organic compound

- cement

- Tecsound

Including acoustic underlays in renovation projects also helps ensure compliance with building insulation standards and soundproofing regulations, providing peace of mind for homeowners and builders alike. Acoustic underlays are also effective for vibration isolation, especially in areas where there are significant sources of vibration, such as near heating equipment or heavy appliances. Acoustic underlays made from polyvinyl chloride (PVC) or cork are ideal choices, as they balance both thermal insulation and soundproofing requirements. This process involves energy transformation, where sound waves are absorbed and converted into heat, which then dissipates harmlessly. Before installing an acoustic underlay, it is important to ensure that the subfloor-whether concrete, particle board, or cement-is clean, level, and dry.

Additionally, these materials are low in volatile organic compound (VOC) emissions, contributing to a healthier indoor environment.

LEED Certified Acoustic Underlays - heat transfer

- sibling

- gypsum drywall

- concrete

- cement

- Tecsound

- sibling

Acoustic underlays installed beneath wood or laminate flooring can significantly reduce noise levels in rooms. By reducing both airborne and impact noise, these underlays contribute to creating a peaceful environment, whether at home, in the office, or in a commercial building.

LEED Certified Acoustic Underlays - volatile organic compound

- sibling

- gypsum drywall

- concrete

LEED Certified Acoustic Underlays - volatile organic compound

- adhesive

- volatile organic compound

- cement